Promise of Good Raw Materials

We only use raw materials that have been checked many times and have passed repeated inspections.

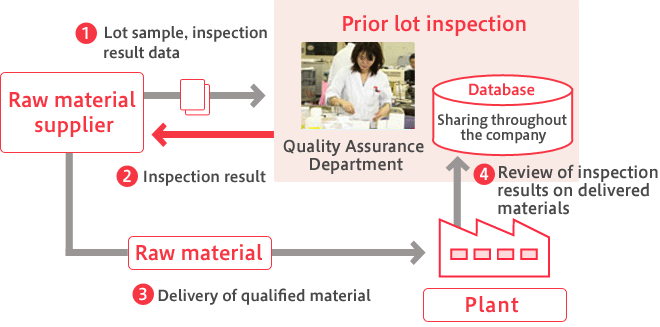

Good products can only be made from high-quality and safe raw materials. We have established a system for conducting "prior lot inspections" from the Raw material procurement phase to support the quality and safety of our products. Samples from every lot are inspected at the Quality Assurance Department before the raw materials are delivered to the plants. Only raw materials that pass the inspection are delivered.

A total of three inspections (triple-check) are conducted after raw materials qualified for quality and safety by prior lot inspections are delivered to the plants: once upon raw material acceptance, once during warehouse storage, and once just before use for production.

When handling raw milk, the principal raw material for milk and dairy products, we thoroughly protect safety and reliability even during transport from the dairy farmer to the plants. We also conduct regular inspections with high-precision analytical instruments to confirm that the materials are completely free of agricultural chemical residues derived from dairy cattle feed or antibiotics used in the treatment of dairy cattle.

[Prior Lot Inspection by Morinaga Milk]

Morinaga Milk confirms raw materials not only through supplier inspections and acceptance inspections at the plants, but also by prior lot inspections operated by the Quality Assurance Department to evaluate the raw materials even more strictly before they are delivered. The Quality Assurance Department conducts prior lot inspections on pre-delivered lot samples of materials scheduled to be shipped in from raw material suppliers. Only accepted products are delivered to the plants and used. The Quality Assurance Department carries out the inspections, evaluates the samples based on the material standards, and publishes the inspection results on the database for the plants that are to use the inspected materials. Every plant confirms the inspection result before accepting a material and then conducts a plant inspection upon delivery to the plant. If a material passes the prior lot inspection but fails the plant inspection, it is either discarded or returned unused. Some plants impose even stricter quality control by configuring their systems to automatically reject any material that fails the prior lot inspection.

Safety and Reliability Delivered from the Dairy Farmer to the Plant

The "Dairy Farm Services Department" at Morinaga Milk is responsible for procuring raw milk. To assure the safety, reliability, and high quality of milk and dairy products with greater precision, personnel from Dairy Farm Services Offices in six locations throughout Japan confirm the safety and sanitation of the raw milk on visits to the dairy farmers who supply the raw milk and to the cooler stations where the milk is collected and relayed. To raise awareness of the importance of safety and reliability throughout the Morinaga Milk Group, a group company called MORINAGA DAIRY SERVICE CO., LTD. partners with the dairy farmers as a seller of good feeds, provider of information on feeding management, and builder of trusting relationships through direct communication.

The person in charge of the Dairy Farm Services Office pays frequent visits to the farmer to establish a cooperative relationship.

[Mechanism to assure safety and reliability from the dairy farmer to the plant]

Dairy farmer

A dairy farmer keeps records on factors related to the safety and reliability of milk, such as the feed content, medications used, raw milk temperature control, and the spraying of agricultural chemicals on pasture grass (the records are confirmed periodically by a third party).

Milk collector

A small collection vehicle visits dairy farmers one by one. The collected milk is brought to a cooler station or dairy plant.

Cooler station※

The cooler station cools milk delivered by the small collection vehicle and temporarily stores it. During storage, the numbers of bacteria and somatic cells are counted and the presence of mixed antibiotics and other items are checked. The raw milk that passes these checkups is then transferred to the dairy plant by a large collection vehicle.

※Cooler station: A facility for cooling and temporarily storing raw milk, usually owned and operated by regional dairy farmer organizations

Residual Agricultural Chemical Verification Test

The quality of raw materials derived from agriculture and livestock products is initially assured by confirming the steps taken by the raw material suppliers to monitor the presence of residual agricultural chemicals (warranty cards, data on analytical results, and so on). Further upstream, we regularly measure residual agricultural chemicals present in major raw materials to confirm that the raw material suppliers are properly managing and guiding the producers without problems. We ensure the safety of raw materials on both levels.

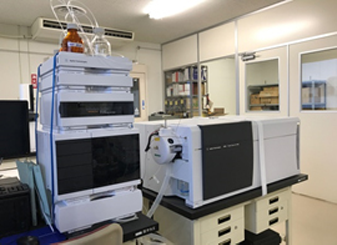

The Quality Assurance Department inspects residual agricultural chemicals with such a device.